Abstract In the sewage treatment process, the stirring machinery is an indispensable equipment supplemented with the completion of the biochemical process,The way and efficiency of the mixer directly affects the final process treatment effect and treatment cost,Based on the stirring methods commonly used in the water treatment process, this article introduces several energy-saving technical reform directions of traditional submersible mixers and an energy-saving, high-efficiency, three-dimensional spiral hyperbolic stirring form--Hyperboloid mixer,It has important economic and social significance for the new sewage treatment project or the upgrade and reconstruction of the existing sewage treatment plant to implement the national energy conservation and emission reduction strategy scientifically.

Keywords:Mix Hyperbola Sewage treatment Energy saving

1 Foreword

Water mixing is one of the key processes in municipal, chemical papermaking and other water treatment processes.Traditional mixing machinery is divided into vertical shaft paddle type, horizontal (submersible) propulsion type and other mixed forms.Because the way of installation and the shape of the blade determine its stirring form, it is not ideal in terms of energy consumption or stirring effect.According to preliminary statistics,the energy consumption of mixing in the wastewater treatment process accounts for nearly 20% of the total energy consumption.In response to the above issues,after many years of research and development of fluid equipment production, with the help of the design experience of peers, we have carried out energy-saving technological transformation of the flow-passing submersible agitation flow-propulsion equipment and achieved preliminary results.At the same time, we jointly developed a hyperboloid mixer with independent intellectual property rights (ZL200620068740.X) together with domestic research institutes.Through years of practical application in Beijing Gaobeidian Sewage Treatment Plant, Shanghai Wusong Sewage Treatment Plant and Shenzhen Water Affairs Group, it has achieved good results,For example, nearly 100 units have been used in the reconstruction and new construction of Changzhou Chengbei Sewage Plant and Changzhou Jiangbian Sewage Plant under Shenzhen Water Affairs Group, which has gained successful experience in large-scale promotion.It fills the gaps of this type of products in China and becomes the first choice for import substitution. Here, we will share some successful experiences in the manufacturing and operation process with colleagues.

2 Technology improvement route

2.1 Submersible mixer

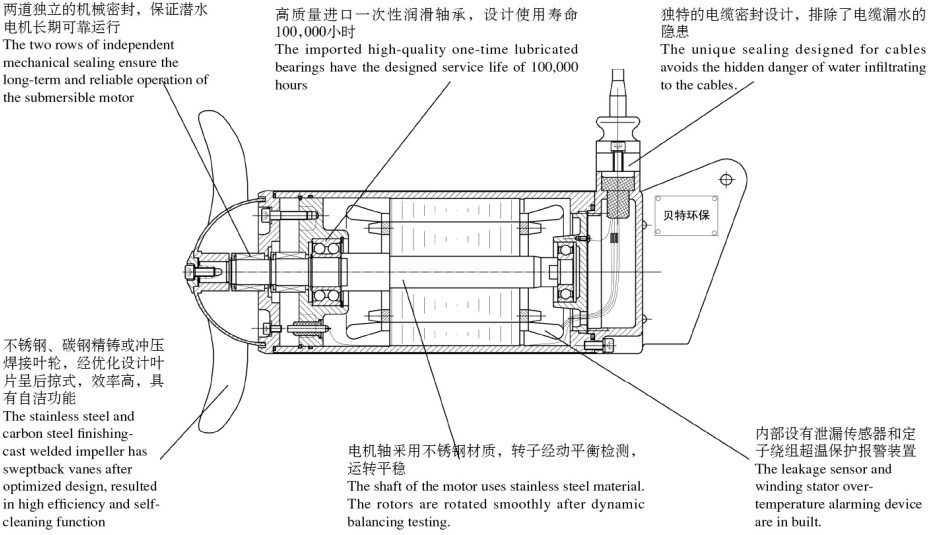

The traditional submersible mixer is a mature product in the sewage treatment process and is widely used in China. It mainly consists of a submersible motor, an impeller and a mounting system ( Figure 1).In order to simplify the structure of the whole machine, multi-stage motors are usually used in conjunction with the direct-connected structure; the impellers are in the form of casting and welding.Although the traditional submersible mixer has the characteristics of compact structure, convenient installation and maintenance, etc., due to the factors of the impeller form and the power equipment scheme, there is a certain room for improvement in energy consumption and efficiency.In view of the above reasons, and considering product reliability, we have made the following four energy-saving technology improvements:

a)High-efficiency impeller—The impeller is a high-speed rotating component, and the casting structure has poor accuracy, which makes it difficult to ensure the balance of the impeller.We re-tested the impeller for hydraulic testing and improved it into a fully stamped welded structure and a swept-back impeller, which has effectively improved hydraulic efficiency and balance.

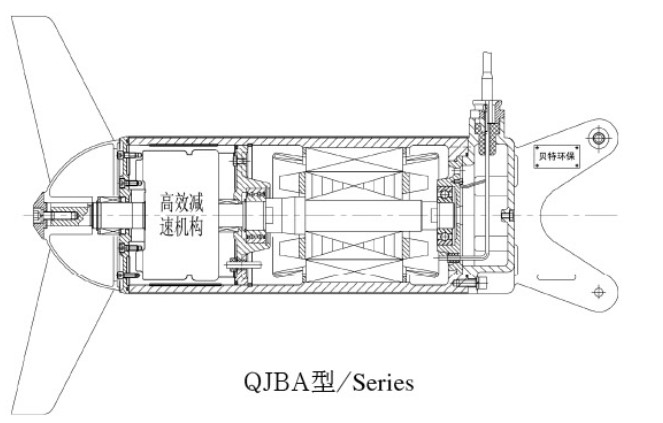

b)Energy saving power—Aiming at the problems of low energy efficiency, large motor size and high cost of multi-stage motors of traditional submersible mixers,We have proposed a power scheme for an integrated high-efficiency helical gear reducer for a conventional four-stage motor.The main components of the improved energy-saving submersible mixer are a submersible motor, a reducer, an impeller and an installation system( Figure 2).Under the same conditions, the overall efficiency can be improved by about 15% compared to multi-stage motors. Examples and comparisons can be found in the following table (Table 1)

Figure1

Figure2

Table 1.Comparison table of energy-saving submersible mixer examples

| Model | Power scheme | Matching motor | Working current | Effective-ness | Power factor | Actual power consumption | Brief Comment on Structure |

|

Conventional type D=620mm; n=480rpm T=2600N | 12P motor | 7.5kW | 25A | 0.69 | 0.56 | 9. 2kwh/H | Relatively simple structure, easy to manufacture and low operating efficiency |

|

|

|

Energy-saving tyoe D=620mm; n=480rpm T=2600N | 4Pmotor+ Helical gear reducer | 7.5kW | 13A | 0.87 | 0.85 | 7.3kwh/H | Relatively complex structure, high production technology requirements and high operating efficiency |

|

|

|

Annual cost savings: 360D*24h*(9.2-7.3=1.9)kwh*0.6yuan/kwh*1set=9849yuan |

|

|

|

|

|

|

|

|

c)Reliable sealing—Submersible mixing is a device that works under liquids. Sealing is the most basic guarantee for reliable operation.In this regard, we design two independent mechanical seals, and set sensors in the oil chamber in the middle of the two mechanical seals, in conjunction with the unique junction box design, to ensure the long-term reliable operation of underwater equipment.

d)Durable design—Aiming at the characteristic that diving mixing usually works continuously for 24 hours,We have selected permanent lubricating bearings with a design life of 100,000 hours. Under normal circumstances, this part is basically guaranteed to be maintenance-free for life.

2.2 Submersible flow propeller

Traditional submersible thrusters are mainly used in oxidation ditch processes and other mixed places.The main structure is: submersible motor, cycloid pinwheel reducer, banana-shaped paddle and installation system.The main problems are the short life of the reducer, low efficiency, and poor impeller efficiency.In response, we made the following three major energy-saving technology improvements:

a)High-efficiency blades—Traditional banana-shaped paddles have been used in China for more than 20 years, and there have been few major technical improvements. There is a lot of room for improvement in terms of structural strength, hydraulic appearance, and rotational balance.In this regard, we re-modeled the hydraulic model of this large-diameter, low-speed blade, and developed a "broad-blade" blade, which has significantly improved its performance.Details can be seen in the comparison below (Table 2):

Table2.Comparison table of blade propeller type performance structure

| Paddle type | Specific surface area | Connection method | Thrust | Energy consumption |

| Traditional shaped paddle | General | Shaft Pin type | General | Higher |

| Broad-Leaf Paddle | Increase by 1/3 | Flanged tyoe | 30% increase | Down 30% |

b)Gear reduction-Due to the inherent structural reasons and domestic assembly quality reasons of the cycloidal pinwheel reducers used in traditional models, there are problems such as short life, high heat generation, and poor efficiency.We have selected a highly efficient helical gear reducer, and solved the technical problems of diving seal, underwater lubrication and integrated assembly of this reducer, so that the overall performance of the machine has been effectively improved.Details can be seen in the comparison below (Table 3):

Table3.Reducer performance comparison table

| Reducer type | Effectiveness | Load | Abrasion | Structure |

| Cycloidal pin wheel | 85% | Poor stability and high fever | More serious | Many scattered parts, poor |

| Helical gear | 95% | Good stability and low fever | General | Compact structure, integrated configuration, high gear and assembly accuracy. |

c)Double guide rod mounting system—Due to the use of helical gear reducers and "broad-blade" blade propellers, the thrust and efficiency are greatly improved, and the double guide rod mounting system can provide a more effective and stable installation effect.Due to the use of helical gear reducers and "broad-blade" blade propellers, the thrust and efficiency are greatly improved. The dual-rail system can provide a more effective and stable installation effect, achieve the effect of extending the service life of the whole machine, and improve the maintainability of the system

2.3 Hyperboloid mixer

In contrast to the Submersible flow mixer, we have developed a three-dimensional spiral mixing method, namely a hyperboloid mixer.It is embodied as a hyperboloid structure formed on the upper surface of the hyperboloid impeller body by a hyperbolic generatrix rotating around the axis of the impeller body.The unique impeller design perfectly combines the fluid features and mechanical movement to the maximum degree.The curved surface of hyperboloid impeller is shaped by the curve of formula xy=b rotating around y axis; in order to cater to the water flowing, the impeller is designed to feed water from the center, on one hand, the turbulent flow is reduced, on the other hand, the pressure of the liquid on the impeller surface is equal and even, therefore the machine will be balanceable in the move ment status.Eight guide vanes are equally distributed on the involute dual cambered surface. The kinetic energy is created with help of the potential energy from the supplementary water fed by the deadweight pressure of the fluid and the centrifugal force by the impeller rotating; the fluid will move along the tangent of the impeller circumference under the condition of acceleration of gravity, with reflection of the pond wall, a circulating water flow is formed from bottom to top, therefore the cross-water flow is fonned in the direction of axial Y and radial X. The structure features and special installation mode (in the bottom of the pond) of the hyperboloid mixer impeller decided the ideal mixing effectiveness, and effectively avoids mixing dead spots. At the same time, because of its large specific surface area impeller can obtain a large area of water exchange.

The hyperboloid impeller mixer consists of a power part, a hyperboloid impeller and installation accessories. In order to meet the requirements of different working conditions, we divide the hyperboloid mixer into dry (vertical shaft) and submersible type according to the installation method Species .

Dry installation,the reduction motor is positioned above the pool through a bridge,Powered by dry-type motor and reducer, reliable work and easy maintenance,It is used in liquids with high solid content, high water temperature and abrasive,Impeller with automatic correction function,After continuous technical improvements, the technical problems of the strength and stiffness of the cantilever shaft have been solved.At present, the shaft is 10 meters long, without underwater bearings, and runs smoothly.

Submersible installation, which eliminates the need for a bridge, uses the submersible motor as the power, uses the equipment's self-weight positioning, and is flexible and convenient to install. It is suitable for deep water and stable water quality, without abrasive water,Water temperature is not greater than 40 ℃, PH value is between 6 ~ 9,It is characterized by no noise and no visual impairment.

In the reconstruction project of Changzhou Chengbei Sewage Plant of Deepwater Group designed by Shanghai Municipal Engineering Design and Research Institute. Using the improved A / A / O process, in which the anaerobic section of the hydrolytic acidification tank has a size of 52 meters × 21 meters, a depth of 9.1 meters, and a depth of 8.1 meters, a total of 60 GSJ-2000 and GSJ-2500 Type hyperboloid mixer, all adopt bridge type installation.The Changzhou Jiangbian Sewage Plant, which was constructed after that, was originally intended to use imported products. Due to the successful use of the Changzhou Chengbei Plant, 36 GSJ-2500 products were finally selected.According to calculations, only the Changzhou Chengbei Wastewater Treatment Plant adopts a hyperboloid mixing power of 165kW, while the traditional mixing device can only solve the "laminar flow", and the circulating flow is far inferior to the hyperboloid mixer.According to the traditional mixing method, the mixing power required is about 243kW It can be seen that its energy saving effect is very obvious.

3 Effects and prospects

The technology-improved submersible mixer, submersible propeller and hyperboloid mixer are energy-saving and efficient mixing and stirring devices, which have wide application prospects in the two-phase solid-liquid or three-phase solid-liquid gas mixing.In addition, with the improvement of society's awareness of environmental protection, national energy conservation and emission reduction policies, and strategic decisions to develop a low-carbon economy, more and more attention has been paid to the efficient and economical treatment of sewage.At present, the effluent standards of various sewage treatment plants are mostly required to be upgraded from Level A to Level B. The requirements for dephosphorization and nitrogen removal are higher, and there is bound to be an urgent demand for key equipment technologies with high efficiency and energy saving.Increasing the anaerobic stirring reaction or the hydrolysis and acidification process is a commonly used method at present, and the mixing equipment is the key equipment of this process section, especially the soft and uniform flow characteristics of the hyperboloid when mixing. It has obvious advantages in energy saving.Therefore, we believe that our technological improvement and innovation will play an important role in sewage treatment process and other mixing and mixing places.